- Home Page

- About Cenmen

- Main Products

- Application Case

- Technical Research

- Cenmen News

- Consultancy Service

more info

All kinds of cable compounding granulating line Wire cable PVC compounding extrusion production line HFFR cable compounding extrusion pelletizing Semicon Shield cable compounding extrusion pelletizing XLPE cable compounding extrusion pelletizing Silane XLPE cable compounding extrusion pelletizing

Engineering plastic modifying compounding pelletizing line Alloy modification---ABS/PC;PA/ABS;PPO/PS, etc compounding extrusion pelletizing production line. Reinforcement modification--PP, PA/GF (glass fiber), carbon fiber compounding extrusion pelletizing production line. Filling modification--PP, PA/talcum powder, CaCO3, Mica barium sulfate, etc compounding extrusion pelletizing production line Toughness modification--PC, ABS/elastomer, rubber, etc compounding extrusion pelletizing production line. Function modification co-compounding extrusion pelletizing production line.

High Efficiency Functional Master batch compounding pelletizing CaCO3 High filler Master Batch compounding pelletizing line High Concentration Carbon Black Master Batch compounding pelletizing line TiO2 White Master Batch compounding pelletizing line Fiber (Polypropylene/Polyester) Master Batch compounding pelletizing line Color Master Batch compounding pelletizing line

Modified material pelletizing line Energy-efficient Petrochemical Polimerization PP powder pelletizing line Green bio-based starch degradation masterbatch compounding pelletizing line Grafting material(compatibilizers) pelletizing line TPE/TPV Elastomer pelletizing line

Updated LFT-D Long Glass Fiber online Molding line On-line Molding production Line of LFT-D

Optimized One-step Compounding extrusion forming line Composite Material Compounding Extrusion Calendering Forming Production Line Polymer Waterproof Membrane Compounding Extrusion Calendering Forming Production Line Cellular Polyethylene Separator For Lead-Acid Accumulator Battery Compounding Extrusion Production Line Super-Critical CO2 Foaming XPS, XPP, XPE Board Forming Production Line TPU Shoe Material (Counter) Compounding Extrusion Forming Production Line High Filling Composite Sheet (Stone Paper) Compounding Extrusion Forming Production Line Environmental Protective High filling Composite Packing Board Compounding Extrusion Forming Production Line Biodegradable Sheet Material Compounding Extrusion Calendering Forming Production Line Free Pre Drying and Crystallization PET Material Extrusion Calendering Forming Production Line

Upgraded One Step Process film casting forming line PVC Functional Film Compounding Extrusion Casting Forming Production Line EVA Solar Usage Functional Film Compounding Extrusion Casting Forming Production Line PP, PE Air permeable Film Compounding Extrusion Casting Stretch Forming Production Line Functional Film Compounding Extrusion Casting/ Leaching/Coating Forming Production Line

Functional Sheet Extrusion Forming line Consumable Powder Materials Compounding Extrusion Milling Production Line Cellular Structure Board Extrusion Forming System Drainage/ Storage Board Extrusion Forming Production Line Spinneret Mattress Extrusion Forming Production Line

Wildly applied in Landscape, Municipal, Architectural and Transportation Engineering, Ex:

Landscape: Garage roof greening, roof garden, roof greening, football field, golf course, bathing field engineering, etc.

Municipal: Road subgrade, subway tunnel, etc.

Architectural: Building foundation or lower floor, basement interior and exterior wall, roof impervious and heat insulation layer, etc.

Transportation: Highway, railway subgrade, embankment and slope protection, etc.

Drainage/ Storage Board Application Characteristics:

Water conductivity and drainage;

Waterproof performance;

Structural protection;

Sound insulation, ventilation and moisture-proof function.

Forming Equipment Introduction and Characteristics:

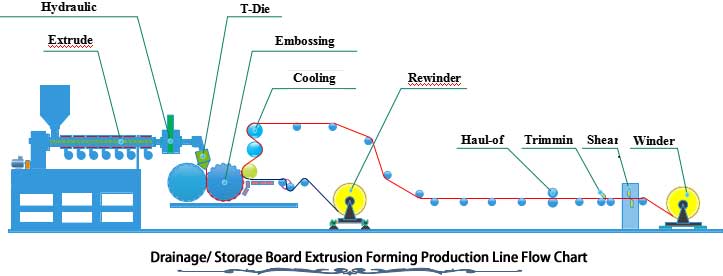

Equipment set composition: Extrusion system, screen changer, hanging type mould die, roller calendering forming machine, cooling tractor, trimming, winder.

Special screw extrusion equipment, enlarge the screen filtration area, suitable for recycled material.

Special design roller calendering technic, final board product thickness uniformity, consistency, higher strength, and has compressive properties;

One-step processing method, power consumption and related transportation, storage and labor costs are saved.

The specially designed drainage plate engraving and milling processing center can effectively ensure the precision of forming and processing, the appearance of the finished products is uniform and beautiful, and the internal quality is stable

Technological process:

Copyright Jiangsu Cenmen Equipment Corp., Ltd@ 2018 China All Rights Reserved