- Home Page

- About Cenmen

- Main Products

- Application Case

- Technical Research

- Cenmen News

- Consultancy Service

more info

All kinds of cable compounding granulating line Wire cable PVC compounding extrusion production line HFFR cable compounding extrusion pelletizing Semicon Shield cable compounding extrusion pelletizing XLPE cable compounding extrusion pelletizing Silane XLPE cable compounding extrusion pelletizing

Engineering plastic modifying compounding pelletizing line Alloy modification---ABS/PC;PA/ABS;PPO/PS, etc compounding extrusion pelletizing production line. Reinforcement modification--PP, PA/GF (glass fiber), carbon fiber compounding extrusion pelletizing production line. Filling modification--PP, PA/talcum powder, CaCO3, Mica barium sulfate, etc compounding extrusion pelletizing production line Toughness modification--PC, ABS/elastomer, rubber, etc compounding extrusion pelletizing production line. Function modification co-compounding extrusion pelletizing production line.

High Efficiency Functional Master batch compounding pelletizing CaCO3 High filler Master Batch compounding pelletizing line High Concentration Carbon Black Master Batch compounding pelletizing line TiO2 White Master Batch compounding pelletizing line Fiber (Polypropylene/Polyester) Master Batch compounding pelletizing line Color Master Batch compounding pelletizing line

Modified material pelletizing line Energy-efficient Petrochemical Polimerization PP powder pelletizing line Green bio-based starch degradation masterbatch compounding pelletizing line Grafting material(compatibilizers) pelletizing line TPE/TPV Elastomer pelletizing line

Updated LFT-D Long Glass Fiber online Molding line On-line Molding production Line of LFT-D

Optimized One-step Compounding extrusion forming line Composite Material Compounding Extrusion Calendering Forming Production Line Polymer Waterproof Membrane Compounding Extrusion Calendering Forming Production Line Cellular Polyethylene Separator For Lead-Acid Accumulator Battery Compounding Extrusion Production Line Super-Critical CO2 Foaming XPS, XPP, XPE Board Forming Production Line TPU Shoe Material (Counter) Compounding Extrusion Forming Production Line High Filling Composite Sheet (Stone Paper) Compounding Extrusion Forming Production Line Environmental Protective High filling Composite Packing Board Compounding Extrusion Forming Production Line Biodegradable Sheet Material Compounding Extrusion Calendering Forming Production Line Free Pre Drying and Crystallization PET Material Extrusion Calendering Forming Production Line

Upgraded One Step Process film casting forming line PVC Functional Film Compounding Extrusion Casting Forming Production Line EVA Solar Usage Functional Film Compounding Extrusion Casting Forming Production Line PP, PE Air permeable Film Compounding Extrusion Casting Stretch Forming Production Line Functional Film Compounding Extrusion Casting/ Leaching/Coating Forming Production Line

Functional Sheet Extrusion Forming line Consumable Powder Materials Compounding Extrusion Milling Production Line Cellular Structure Board Extrusion Forming System Drainage/ Storage Board Extrusion Forming Production Line Spinneret Mattress Extrusion Forming Production Line

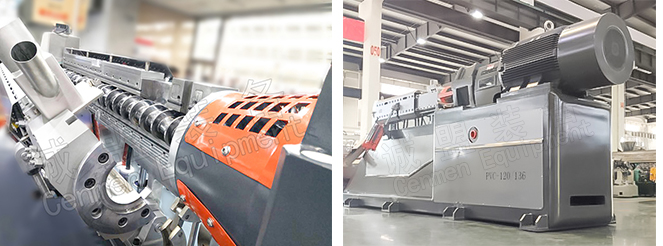

Equipment configuration description for black Polypropylene/Polyester Master Batch:

Polyester Master Batch and Polypropylene Master Batch mainly are black master batch, mainly used in textile filaments and short fibers. The optimal choice of equipment is GWH high performance 4-flight reciprocating kneader to ensure the uniformity of dispersion and distribution of carbon black. In particular, the extrusion temperature of the polyester masterbatch in production can be effectively controlled to avoid the brittleness of the finished product after overheating. The large groove deep structure of the reciprocating kneader screw effectively ensures the accurate feeding of the carbon black powder. The special mixing principle fully ensures the uniform distribution of carbon black in the resin. The flexible low-temperature mixing principle effectively controls the extrusion temperature of the material, so that the material reaches a certain tensile strength, and to produce medium and high-end polyester masterbatch and polypropylene masterbatch.

GWH series Reciprocating Kneader Model:

Model | Barrel inner dia.(mm) | L/D | Main motor power(kw) | Max. rpm | Output (kg/h) | |

GWH series high performance 4-flight Reciprocating kneader | GWH-105 | 105 | 20-25 | 200-250 | 600 | 700-900 |

GWH-125 | 125 | 20-25 | 400-450 | 500 | 1200-1500 | |

GWH-140 | 140 | 20-25 | 500-550 | 500 | 1500-2000 | |

Equipment configuration description for Color Polypropylene/Polyester Master Batch:

The optimal choice of equipment for Color Polyester and Polypropylene Master Batch is GWH high performance 4-flight reciprocating kneader. Due to the variety of colors for color fiber masterbatch, and the output per batch is low, so the GWH series reciprocating kneader should use GWH-58 and GWH-85 reciprocating kneader. During the production process, the equipment needs to be cleaned when changing batches. The most difficult thing to clean is the cleaning of the feeder. Some pigments are attached to the surface of the feeder and cannot be erased. Only can use alcohol etc the medium to clean. The newly developed feeder that can be quickly disassembled and cleaned on site , the feeder that all in contact with the materials are made of stainless steel, and the time for disassembly and reassembly is less than 10 minutes.

GWH series Reciprocating Kneader Model:

Model | Barrel inner dia.(mm) | L/D | Main motor power(kw) | Max. rpm | Output (kg/h) | |

GWH series high performance 4-flight Reciprocating kneader | GWH-58 | 58 | 20-25 | 30-37 | 600 | 80-100 |

GWH-85 | 80 | 20-25 | 110-132 | 600 | 250-400 | |

Copyright Jiangsu Cenmen Equipment Corp., Ltd@ 2018 China All Rights Reserved