- Home Page

- About Cenmen

- Main Products

- Application Case

- Technical Research

- Cenmen News

- Consultancy Service

more info

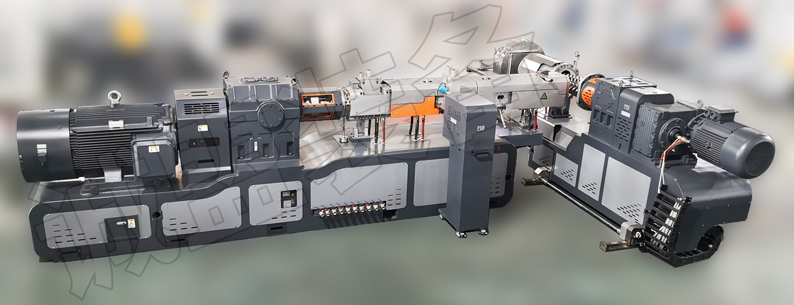

All kinds of cable compounding granulating line Wire cable PVC compounding extrusion production line HFFR cable compounding extrusion pelletizing Semicon Shield cable compounding extrusion pelletizing XLPE cable compounding extrusion pelletizing Silane XLPE cable compounding extrusion pelletizing

Engineering plastic modifying compounding pelletizing line Alloy modification---ABS/PC;PA/ABS;PPO/PS, etc compounding extrusion pelletizing production line. Reinforcement modification--PP, PA/GF (glass fiber), carbon fiber compounding extrusion pelletizing production line. Filling modification--PP, PA/talcum powder, CaCO3, Mica barium sulfate, etc compounding extrusion pelletizing production line Toughness modification--PC, ABS/elastomer, rubber, etc compounding extrusion pelletizing production line. Function modification co-compounding extrusion pelletizing production line.

High Efficiency Functional Master batch compounding pelletizing CaCO3 High filler Master Batch compounding pelletizing line High Concentration Carbon Black Master Batch compounding pelletizing line TiO2 White Master Batch compounding pelletizing line Fiber (Polypropylene/Polyester) Master Batch compounding pelletizing line Color Master Batch compounding pelletizing line

Modified material pelletizing line Energy-efficient Petrochemical Polimerization PP powder pelletizing line Green bio-based starch degradation masterbatch compounding pelletizing line Grafting material(compatibilizers) pelletizing line TPE/TPV Elastomer pelletizing line

Updated LFT-D Long Glass Fiber online Molding line On-line Molding production Line of LFT-D

Optimized One-step Compounding extrusion forming line Composite Material Compounding Extrusion Calendering Forming Production Line Polymer Waterproof Membrane Compounding Extrusion Calendering Forming Production Line Cellular Polyethylene Separator For Lead-Acid Accumulator Battery Compounding Extrusion Production Line Super-Critical CO2 Foaming XPS, XPP, XPE Board Forming Production Line TPU Shoe Material (Counter) Compounding Extrusion Forming Production Line High Filling Composite Sheet (Stone Paper) Compounding Extrusion Forming Production Line Environmental Protective High filling Composite Packing Board Compounding Extrusion Forming Production Line Biodegradable Sheet Material Compounding Extrusion Calendering Forming Production Line Free Pre Drying and Crystallization PET Material Extrusion Calendering Forming Production Line

Upgraded One Step Process film casting forming line PVC Functional Film Compounding Extrusion Casting Forming Production Line EVA Solar Usage Functional Film Compounding Extrusion Casting Forming Production Line PP, PE Air permeable Film Compounding Extrusion Casting Stretch Forming Production Line Functional Film Compounding Extrusion Casting/ Leaching/Coating Forming Production Line

Functional Sheet Extrusion Forming line Consumable Powder Materials Compounding Extrusion Milling Production Line Cellular Structure Board Extrusion Forming System Drainage/ Storage Board Extrusion Forming Production Line Spinneret Mattress Extrusion Forming Production Line

Equipment Characteristic:

The production process is continuous and the degree of automation is high. The whole production process of semicon shield cable material is a kind of continuous production process, which completes the whole production process from raw material to finished product particles. The conveying, weighing and feeding of raw materials and compounding pelletizing of the process are controlled automatically to improve the production efficiency and reduce the labor cost.

The production link is more environment-friendly. The raw material supply link in production adopts the weight loss electronic scale to feed according to the proportion, and the automatic feeding and transportation system. The storage, metering and transportation of raw materials are connected by pipes and valves, which can effectively reduce the dust pollution in the production workshop. At the same time, the fully closed production process effectively prevents the external impurities from mixing into the product, which is beneficial to the electrical stability of the product.

The product quality is stable and suitable for extrusion cable. The raw material supply and compounding pelletizing link of reciprocating extruder are a kind of continuous and automatic production process. The distribution ratio of each raw material group is accurate, the dispersion is uniform, the cable material produced is more stable in mechanical properties, electrical properties, apparent and so on, and the fluctuation of volume resistance is less than 15 Ω. Cm.

Good mixing and dispersion effect, special flexible compounding mechanism. The conductive carbon black is dispersed evenly in the resin, thus improving the physical and conductive properties of the cable material. The material is subjected to instantaneous high frequency shear, tension and split flow effect, so it has excellent mixing effect of dispersion and distribution, and the mixing effect is more than 20 times of that of twin-screw extruder.

The energy consumption ratio is reduced and the power of the equipment host is greatly reduced. The above special flexible mixing principle makes it have excellent mixing and dispersion effect and lower energy consumption ratio at the same time, and it can reduce the energy by more than 20% at the same output compared with the twin-screw extruder.

High working volume, resulting in a significant increase in production. The screw and barrel of reciprocating mixing extruder have higher working volume and can maintain high extrusion output. At the same time, the intermittent screw interacts with the pin to make it have a good self-cleaning effect.

It is widely used in Jiangsu Yixing, Taicang and Shanghai, Hebei, Guangdong districts, at the same time exproted to Russia, Vietnam, etc.

Copyright Jiangsu Cenmen Equipment Corp., Ltd@ 2018 China All Rights Reserved